As the insurance market continues to see an increase in the complexity of risks being underwritten, the techniques used by property adjusters, damage appraisers and forensic engineers must adapt. Three-dimensional (3-D) laser scanning allows adjusters and investigators to not only document the scope of damage digitally and in real time, but provides data that can be used by risk management and underwriting teams for future risk assessments.

Accurate documentation and preservation of evidence is a critical component of any forensic investigation. The use of 3-D laser scanning enables an investigator to document a complex object or an entire accident scene in the form of millions of measurable points, often in less time than traditional methods. Not only is the level of documentation detail staggering, but the scanner can measure objects considered immeasurable just a few years ago.

In their simplest form, 3-D scanners utilize lasers to generate three-dimensional copies to millimeter accuracy of complex, real-life objects and environments. The end result of a single scan is a collection of millions of measurable data points containing relative x, y, z locations. A series of scans are then stitched together to create an exact color copy of the as-built condition, scene or environment. In the same way that a digital camera, a tape measure and graph paper are tools of the forensic investigator, 3-D documentation is increasingly becoming an asset in the same toolbox.

The 3-D scanners capture everything from the irregularity of a hairline crack in a plaster wall to the vastness of the interior of an industrial warehouse still smoldering from a fire the night before; from the length, depth and curvature of a tire mark left on an asphalt street to the compaction depth of the hood of a vehicle involved in a collision; from the tread and risers of a staircase to the slope and paint stripe location of a crosswalk that extends to a big-box retailer's front door. The application of the scanner is limited only by the creative application of the equipment's operator.

What are the benefits?

Time

The time an engineer spends onsite evaluating a property claim significantly decreases using a 3-D scanner. While the engineer and claims adjuster conduct the investigation, the 3-D scanner can run in the background, taking millions of measurements in minutes. This potentially results in reduced time (and cost) than it would have taken to achieve the same level of documentation using traditional methods.

Accuracy

With one million data points collected per second, an investigator can gather critical measurements as well as those which seem insignificant at the time, but may later prove to be critical to a case. With accuracy of up to +/- 2mm and a range of up to 330m, the data collected is remarkably accurate. This may be significant when a property claim occurs on a dynamic site, one that has changed between the date of loss and when a notice or suit is filed. Being able to document a scene as soon as possible digitally and in complete 3-D accuracy is extremely valuable, especially when a building or business needs to get back online to avoid increasing business interruption claims.

Safety

Scanner use can enhance the safety of those needing to respond to a claim. For example, the scanner has been used for industrial building collapses that were too unstable to allow investigators and engineers close enough to investigate. Instead, the scanner was set up outside of the cordoned-off area and documented the entire mountain of rubble so the scene could be preserved for future analysis. When vehicle accidents occur on busy highway arteries, the digital scanning of a scene can keep the road open and investigators out of harm's way. The scanner can capture the scene from a safe distance, and any irrelevant vehicles or people can be removed during the post processing of scan data.

Reliability

The 3-D data points are collected and transferred in accordance with ASTM E2807, the standard specification for 3-D data collection and exchange. This specification describes a data file exchange format for three-dimensional imaging data, known as the ASTM E57 3-D file format. This has enabled scan data to be introduced and accepted as evidence into state and federal courts. This may also include visualizations or animations produced from the 3-D data originally collected.

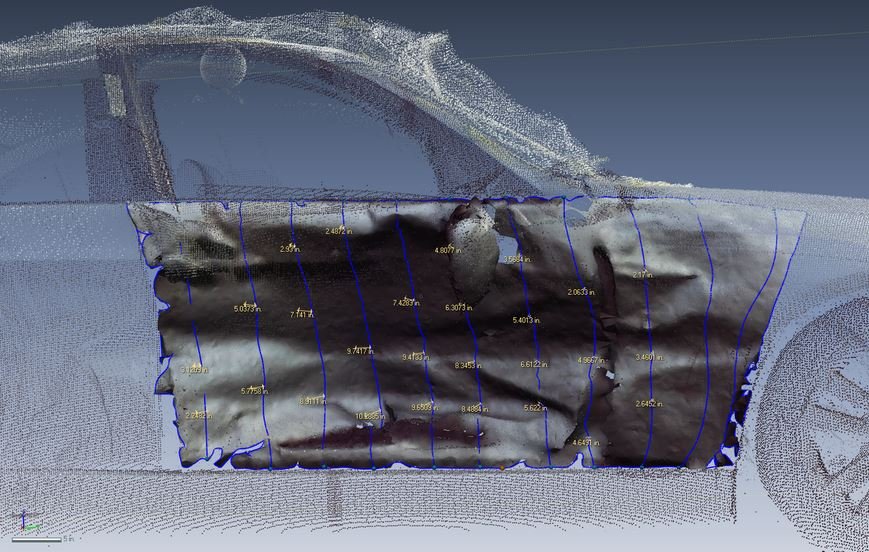

Vehical accident reconstruction. (Photo: S-E-A, Ltd.)

Common Applications

Vehicle accident reconstruction

The reconstruction of an accident begins with the collection of facts and measurements. Using 3-D documentation enables the investigators to have an endless number of both at their disposal. In an accident reconstruction, knowing the crush stiffness and crush profile allows for the calculation of crush energy. With 3-D documentation, crush profiles can be documented with increased speed and accuracy over traditional documentation methods. It also provides additional data for any future crush analyses if needed.

Scan of an apartment fire. (Photo: S-E-A, Ltd.)

Structure fires

A fire engulfs a building and is eventually controlled by firefighters. Fire investigators are called to the scene to document the resulting loss. Under normal circumstances, completely documenting something as amorphous as a fire scene would be nearly impossible. However, armed with a 3-D scanner, a fire investigator can obtain data points of the exterior of the structure, thus digitally preserving the scene and offering investigators an easy way to measure necessary points well after the eventual demolition of the building.

Structure collapse scan. (Photo: S-E-A. Ltd.)

Structural collapse evaluation

This photo shows the point cloud of an 11-story steel building that was scheduled for demolition. It collapsed prematurely, killing the demolition contractor. The scene was preserved from a distance and without interruption to the first responders. It shows how engineers can use the high definition (HD) panoramic photos captured by the scanner (which are used to colorize the data points collected) to assist in an evaluation. Engineers can zoom into the photos and measure the data points associated with the steel plates, bolt configurations, web stiffeners and the like. This is performed by accessing the actual data points collected, not by applying traditional photogrammetry software packages. This allows for millimeter accuracy within an HD field of vision.

Bridge collapse close-up. (Photo: S-E-A, Ltd.)

Bridge damage evaluation

The use of 3-D documentation is not limited to evidence preservation, accident reconstruction or trial animation. It also allows the engineer to facilitate efficient and accurate evaluation of the collected data to assist in the risk mitigation and risk transfer phases of the case management life cycle. When a tractor-trailer damages the underside of a multi-lane freeway overpass, timely understanding of the extent of the damage and appropriate remediation measures is required. A setting with emergency repair operations taking place or vehicles racing past investigators at more than 65 mph may not allow for accurate documentation of the damage. Shutting the freeway down is expensive and many times infeasible. Along with accurate documentation of the damaged overpass from a safe distance, demonstrative figures can be produced to objectively communicate the facts, allowing for expedited resolution of the proposed repair protocols and associated costs.

Construction truss scan. (Photo: S-E-A, Ltd.)

Construction sites

Sometimes the investigator is called in long after the occurrence in question. Construction sites, like accident sites, are in a dynamic state which can occasionally impede the evaluation. In many cases, it is nearly impossible to recreate the conditions at the time of the accident. Site information gathered utilizing 3-D documentation can be efficiently merged with other data such as construction plans and aerial photographs of the accident scene to accurately recreate the accident site. This data is analyzed to produce diagrams that will graphically illustrate the conditions at the time of the accident.

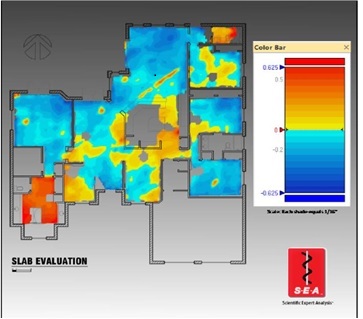

Slab evaluation. (Photo: S-E-A, Ltd.)

Floor elevation map

Utilizing 3-D documentation can allow for repeatable data collection and measurements to sub-millimeter accuracy. It can also eliminate potential errors associated with traditional data collection methods. For example, a floor can be documented to such a detailed level that the construction tolerances for the slab/framing and floor finishes can be accounted for. This data can be analyzed to produce diagrams that will graphically illustrate elevation changes throughout the floor at a single point in time, or visually show deviations that occur during an extended period of time. This allows for visualizations that emphasize the vital details in an investigation.

Modeling/animation

While the value of 3-D documentation, with respect to evidence preservation, is clearly evident, it extends beyond the initial investigation, enabling advanced visualization and simulations. This underscores the importance of presenting the necessary facts in a clear and impactful manner. A video based upon real-life data gathered via 3-D documentation can make all the difference in the pursuit to convey "what happened" to a jury.

The use of 3-D laser scanning does not replace the engineer or investigator on a scene or their analysis. Traditional forensic engineering methodology coupled with the revolutionary technology of 3-D scanning has changed the way investigators document a scene and utilize site data. Litigation visualizations can be produced with the resulting data to a degree of accuracy that was previously difficult to imagine. This scanning technology also allows investigators to document minute details so as to be prepared regardless of changes to a site or the direction the case takes, all while maintaining safety and reducing costs. A 3-D scan captures today, so the information can be used tomorrow.

Ryan Siekmann is a national sales executive for S-E-A, Ltd. focusing on the automotive, legal and manufacturing sectors. Over the past nine years with S-E-A, Ryan has held various roles, including regional sales representative for S-E-A's Baltimore office and manager of sales for S-E-A's Fire/Explosion and Vehicle Dynamics Practice Groups. He can be reached at [email protected].

Want to continue reading?

Become a Free PropertyCasualty360 Digital Reader

Your access to unlimited PropertyCasualty360 content isn’t changing.

Once you are an ALM digital member, you’ll receive:

- Breaking insurance news and analysis, on-site and via our newsletters and custom alerts

- Weekly Insurance Speak podcast featuring exclusive interviews with industry leaders

- Educational webcasts, white papers, and ebooks from industry thought leaders

- Critical converage of the employee benefits and financial advisory markets on our other ALM sites, BenefitsPRO and ThinkAdvisor

Already have an account? Sign In Now

© 2024 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.