With our fifth annual National Underwriter “Awards For Excellence In Workers' Compensation Risk Management,” sponsored by the National Council on Compensation Insurance, we again highlight examples of outstanding loss control, safety and return-to-work programs.

With our fifth annual National Underwriter “Awards For Excellence In Workers' Compensation Risk Management,” sponsored by the National Council on Compensation Insurance, we again highlight examples of outstanding loss control, safety and return-to-work programs.

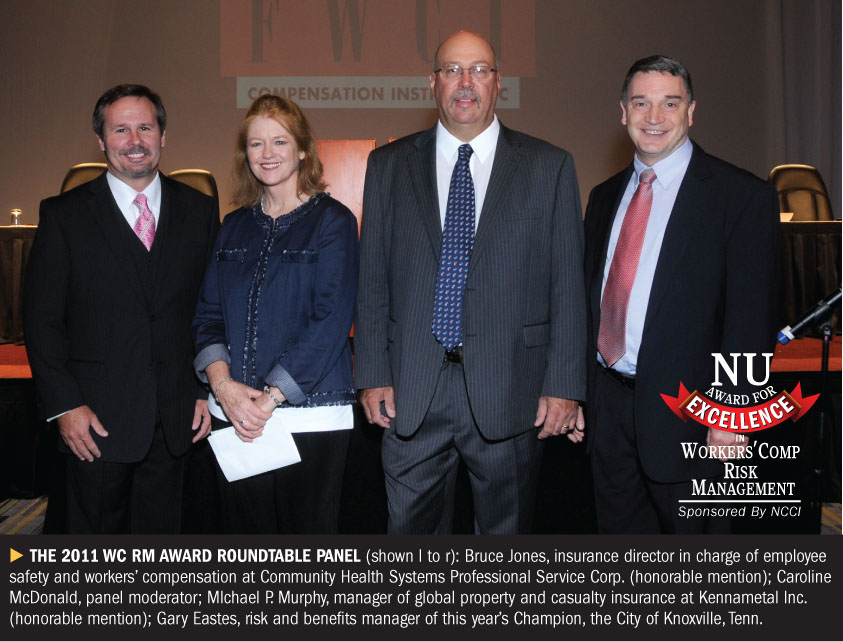

This year's awards were presented to three innovative organizations:

- The City of Knoxville, Tenn. (this year's Champion and our first-ever public-sector award winner)

- Kennametal Inc. (Honorable Mention)

- Community Health Systems (CHS) Professional Service Corp. (Honorable Mention)

In addition to the company profiles featured in the Aug. 22/29 issue of National Underwriter, the risk managers from these award-winning companies participated in a roundtable discussion at the Workers' Compensation Educational Conference in Orlando on Aug. 23.

The panel was part of the “National Trends Program” put together by NU in conjunction with the conference organizer, the Florida Workers' Compensation Institute. Caroline McDonald, NU's assistant managing editor, moderated.

Recommended For You

Want to continue reading?

Become a Free PropertyCasualty360 Digital Reader

Your access to unlimited PropertyCasualty360 content isn’t changing.

Once you are an ALM digital member, you’ll receive:

- Breaking insurance news and analysis, on-site and via our newsletters and custom alerts

- Weekly Insurance Speak podcast featuring exclusive interviews with industry leaders

- Educational webcasts, white papers, and ebooks from industry thought leaders

- Critical converage of the employee benefits and financial advisory markets on our other ALM sites, BenefitsPRO and ThinkAdvisor

Already have an account? Sign In Now

© 2025 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.