Because of a belief that its workforce is its No. 1 advantage, Kennametal Inc. refuses to compromise when it comes to protecting them.

The company, which believes employees should go home in the same condition in which they arrived, has initiated a “100% Safe” program with the goal of zero injuries to workers, says Michael P. Murphy, manager of global property and casualty insurance with Kennametal, headquartered in Latrobe, Pa., where it was founded in 1938.

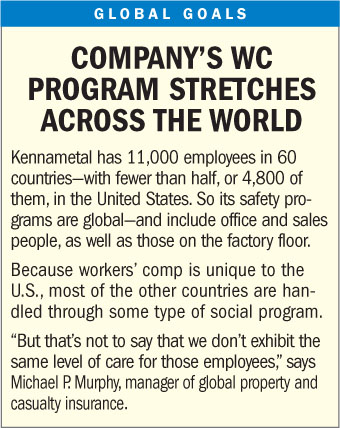

Kennametal, a Fortune 1000 company with 11,000 employees and $2.4 billion in sales, manufactures metal-product solutions for a wide range of industries, including aerospace, transportation, mining and construction.

Kennametal, a Fortune 1000 company with 11,000 employees and $2.4 billion in sales, manufactures metal-product solutions for a wide range of industries, including aerospace, transportation, mining and construction.

The company's business culture and strategic decision making, Murphy explains, are founded upon six core values: People, Environment, Integrity, Innovation, Performance and Customers.

Kennametal's commitment to its people—the first of the six values—is the foundation upon which its 100% Safe program was built, Murphy says.

He adds that the core values are demonstrated “across the company, from the very highest leadership level down throughout the ranks,” beginning with CEO Carlos Cardoso, who is integrally involved in the company's Environmental Health and Safety program.

The relentless pursuit to achieve 100% Safe, he says, “has transformed the company.”

This pursuit, as well as the company's loss prevention, claims handling and other programs, have earned Kennametal an award in the fifth annual National Underwriter Award for Excellence in Workers' Compensation Risk Management program, sponsored by NCCI.

AMBITIOUS AIM: CUT COSTS IN HALF

AMBITIOUS AIM: CUT COSTS IN HALF

In October 2007, Kennametal's risk-management team announced a stretch goal of reducing workers' comp costs by 50 percent—from $2.8 million to $1.4 million—by 2010, while enhancing service to employees.

The two areas targeted for generating these savings were:

- Enhanced loss prevention.

- Improved claims handling, with claims management separated further by “lost time” and “medical only.”

The goal was realized—and surpassed—

a year early, by June 30, 2009.

Significant loss-prevention efforts, coupled with improved claims management, resulted in workers' comp costs being reduced by 59 percent in a three-year time period (2008-2010).

Murphy has been able to accomplish all this with “one-and-a-half full-time employees dedicated to risk management. So that makes having effective processes in place critical,” he says.

In fact, solid processes and a dedicated team of third-party experts helped the company go from 200 open workers' comp claims down to 48. Doing this has allowed Murphy to assume additional responsibilities “along with continuing to effectively manage workers' comp costs,” he says.

DIVING INTO THE DETAILS

DIVING INTO THE DETAILS

The initial focus of the cost-reduction initiative was reducing lag time—the time from occurrence of the injury to reporting to the carrier.

Lag time was ultimately reduced from about 30 days to 3.72 days. “I'm a firm believer that reducing lag time will help to reduce workers' comp costs,” Murphy observes.

This was achieved by focusing on the processes with a general initiative to build speed into the program all the way through to resolution.

This was achieved by focusing on the processes with a general initiative to build speed into the program all the way through to resolution.

Building speed into the program “sends a powerful message to the workforce that there is a strong commitment here to make sure our employees are properly taken care of,” he says.

As an added bonus, while a very low percentage of workers' comp claims are fraudulent or questionable in nature, reducing lag time “also serves to send a message in these instances as well,” Murphy says.

The workforce understands that the company “takes this seriously and each incident is looked at carefully,” he explains.

Over the last couple of years, he adds, the majority of injuries have been hand related; and beyond that, slips and falls. A number of initiatives have been introduced to reduce hand injuries, “and they have been effective,” he says.

A large part of the management-based safety process is a checklist for reviewing the work area for hazards and to assure that the proper protective equipment is worn.

Part of the message to employees is that “certain behaviors won't be tolerated,” Murphy says. “Anyone who violates a “cardinal rule, defined within the company's policy, is subject to disciplinary action, up to and including termination. So that is taken very seriously.”

When the initial announcement was made about the expectation of injury reductions, a culture of accountability and consequences was established, with facilities “feeling the pain for poor performance in the pocketbook,” Murphy notes.

But in addition to the stick, there is also a carrot, and facilities have learned that keeping injuries down and reducing costs pays.

Each facility contributes to the workers' comp costs pool. However, over the last several years, “we've had such good performance that at year-end, they have received a reimbursement. Many of our locations received half of what they paid back—that's after 20 percent reduction a year for the past three years.”

Murphy adds, “We encourage them to celebrate the success.” The money also gives the facilities “capital investment for improvement that makes them more competitive on a global basis.”

Want to continue reading?

Become a Free PropertyCasualty360 Digital Reader

Your access to unlimited PropertyCasualty360 content isn’t changing.

Once you are an ALM digital member, you’ll receive:

- Breaking insurance news and analysis, on-site and via our newsletters and custom alerts

- Weekly Insurance Speak podcast featuring exclusive interviews with industry leaders

- Educational webcasts, white papers, and ebooks from industry thought leaders

- Critical converage of the employee benefits and financial advisory markets on our other ALM sites, BenefitsPRO and ThinkAdvisor

Already have an account? Sign In Now

© 2024 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.